Building a Gesture -Bluetooth-Controlled Robot Car Using Arduino & MPU6050: Complete Guide

Today, we are going to build an exciting robotics project where an Arduino-based robot car is controlled using the MPU6050 sensor (Accelerometer & Gyroscope) and Bluetooth communication. The MPU6050 sensor will detect hand movements and translate them into motion commands, which will be sent via an HC-05 Bluetooth module to control the robot car’s movement in real time.

Additionally, to make the robot more autonomous, we will integrate an HC-SR04 Ultrasonic Sensor. This sensor will continuously monitor the surroundings and detect obstacles in the path of the robot. If an obstacle is detected, the robot will automatically stop or change direction to avoid collisions, making it a smart and efficient system.

This project is perfect for students, hobbyists, and tech enthusiasts who are eager to explore robotics, microcontrollers, and IoT. It provides hands-on experience in working with motion sensors, wireless communication, and obstacle detection, making it a great learning opportunity for anyone interested in building intelligent robotic systems.

Required Components

To build this robot car, you will need the following components:

| No. | Component | Quantity |

|---|---|---|

| 1 | Arduino Uno | 1 |

| 2 | MPU6050 (Accelerometer & Gyroscope Sensor) | 1 |

| 3 | HC-05 Bluetooth Module | 1 |

| 4 | L298N Motor Driver Module | 1 |

| 5 | DC Motor (Wheel Motor) | 4 |

| 6 | HC-SR04 Ultrasonic Sensor | 1 |

| 7 | 9V Battery / Li-ion Battery Pack | 1 |

| 8 | Jumper Wires & Battery Connectors | As needed |

| 9 | Robot Car Chassis | 1 |

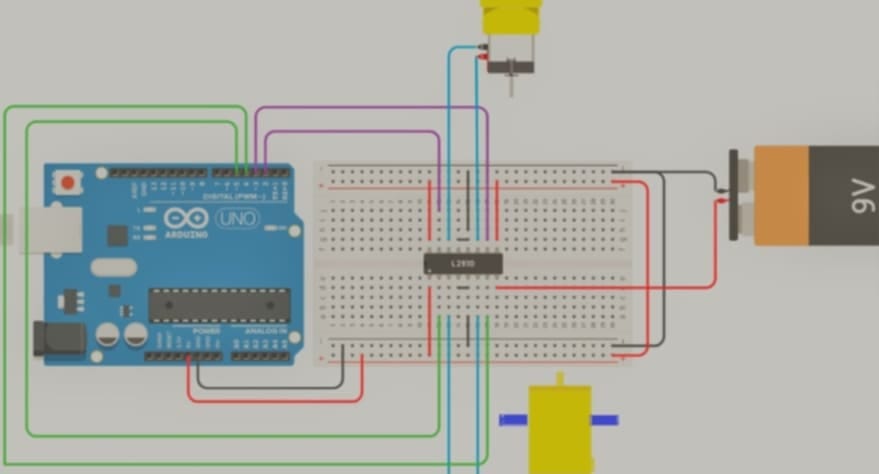

Circuit Connections

1. Connecting MPU6050 (Accelerometer & Gyroscope):

- VCC → 5V (Arduino)

- GND → GND (Arduino)

- SCL → A5 (Arduino)

- SDA → A4 (Arduino)

2. Connecting HC-05 Bluetooth Module:

- VCC → 5V (Arduino)

- GND → GND (Arduino)

- TX → 11 (Arduino)

- RX → 10 (Arduino) [Use a 1KΩ & 2KΩ voltage divider]

3. Connecting L298N Motor Driver:

- IN1 → 3 (Arduino)

- IN2 → 5 (Arduino)

- IN3 → 6 (Arduino)

- IN4 → 9 (Arduino)

- Motor A (Left) → M1 & M2

- Motor B (Right) → M3 & M4

- 12V → Battery positive terminal

- GND → Battery negative terminal

4. Connecting HC-SR04 Ultrasonic Sensor:

- VCC → 5V (Arduino)

- GND → GND (Arduino)

- Trig → 12 (Arduino)

- Echo → 13 (Arduino)

Arduino Code Explanation

1. Reading Data from Gesture MPU6050

#include <Wire.h>

const int MPU=0x68;

float AccX, AccY, AccZ;

float pitch, roll;

void setup(){

Wire.begin();

Wire.beginTransmission(MPU);

Wire.write(0x6B);

Wire.write(0);

Wire.endTransmission(true);

Serial.begin(9600);

}

void loop(){

Wire.beginTransmission(MPU);

Wire.write(0x3B);

Wire.endTransmission(false);

Wire.requestFrom(MPU, 6, true);

AccX = (Wire.read() << 8 | Wire.read()) / 16384.0;

AccY = (Wire.read() << 8 | Wire.read()) / 16384.0;

AccZ = (Wire.read() << 8 | Wire.read()) / 16384.0;

pitch = atan(AccY / sqrt(AccX * AccX + AccZ * AccZ)) * 180 / PI;

roll = atan(-AccX / sqrt(AccY * AccY + AccZ * AccZ)) * 180 / PI;

Serial.print("Pitch: "); Serial.print(pitch);

Serial.print(" Roll: "); Serial.println(roll);

delay(100);

}

This code reads the pitch and roll values from the MPU6050 sensor to detect hand gestures.

2. Receiving Bluetooth Commands and Controlling the Robot

#include <SoftwareSerial.h>

SoftwareSerial BTSerial(10, 11); // HC-05 connection

void setup() {

BTSerial.begin(9600);

pinMode(3, OUTPUT);

pinMode(5, OUTPUT);

pinMode(6, OUTPUT);

pinMode(9, OUTPUT);

}

void loop() {

if (BTSerial.available()) {

char command = BTSerial.read();

if (command == 'F') { // Move forward

digitalWrite(3, HIGH);

digitalWrite(5, LOW);

digitalWrite(6, HIGH);

digitalWrite(9, LOW);

} else if (command == 'B') { // Move backward

digitalWrite(3, LOW);

digitalWrite(5, HIGH);

digitalWrite(6, LOW);

digitalWrite(9, HIGH);

} else if (command == 'L') { // Turn left

digitalWrite(3, LOW);

digitalWrite(5, HIGH);

digitalWrite(6, HIGH);

digitalWrite(9, LOW);

} else if (command == 'R') { // Turn right

digitalWrite(3, HIGH);

digitalWrite(5, LOW);

digitalWrite(6, LOW);

digitalWrite(9, HIGH);

} else { // Stop

digitalWrite(3, LOW);

digitalWrite(5, LOW);

digitalWrite(6, LOW);

digitalWrite(9, LOW);

}

}

}

This code processes Bluetooth commands and moves the robot accordingly.

3. Obstacle Detection and Avoidance

This code uses an ultrasonic sensor to detect obstacles and stop the robot if needed.

Receiver cod

#include <SoftwareSerial.h>

SoftwareSerial BTSerial(10, 11); // CONNECT BT RX PIN TO ARDUINO 12 PIN | CONNECT BT TX PIN TO ARDUINO 11 PIN

#include<SPI.h>

int trigPin = 12; // Trig

int echoPin = 13; // Echo

long duration, cm, inches;

int direct;

int l1=3;

int r1=5;

int l2=6;

int r2=9;

int forword_corr;

int a = 0 ;

int s = 3;

int b = 0 ;

int c = 2;

void setup() {

Serial.begin(9600);

BTSerial.begin(9600);

pinMode(l1, OUTPUT);

pinMode(r1, OUTPUT);

pinMode(l2, OUTPUT);

pinMode(r2, OUTPUT);

digitalWrite(l1, LOW);

digitalWrite(r1, LOW);

digitalWrite(l2, LOW);

digitalWrite(r2, LOW);

pinMode(trigPin, OUTPUT);

pinMode(echoPin, INPUT);

}

void loop() {

digitalWrite(trigPin, LOW);

delayMicroseconds(5);

digitalWrite(trigPin, HIGH);

delayMicroseconds(10);

digitalWrite(trigPin, LOW);

pinMode(echoPin, INPUT);

duration = pulseIn(echoPin, HIGH);

cm = (duration/2) / 29.1; // Divide by 29.1 or multiply by 0.0343

Serial.print(cm);

Serial.print("cm");

Serial.println();

if(BTSerial.available()>0){ // Witing for data incoming from the other XBee module

direct=BTSerial.read();

if(direct == 'B'){

Serial.println("Backward");

backward();

}else if (direct=='F'){

Serial.println("Forward");

forward();

}else if(direct == 'R'){

Serial.println("Right");

left();

}else if(direct == 'L'){

Serial.println("left");

right();

}else if(direct == 'r'){

Serial.println("rotright");

rotr();

}else if(direct == 'l'){

Serial.println("rotleft");

rotl();

}else if (direct == 'S'){

Serial.println("Stop");

stopCar();

}

}

}

void forward()

{

if(cm<=15){

digitalWrite(l1, LOW);

digitalWrite(r2, LOW);

}

else{

digitalWrite(l1, HIGH);

digitalWrite(r1, LOW);

digitalWrite(l2, LOW);

digitalWrite(r2, LOW);

delay(2);

digitalWrite(r2, HIGH);

delay(2);

}

}

void backward()

{

digitalWrite(l1, LOW);

digitalWrite(l2, HIGH);

digitalWrite(r2, LOW);

if(b%c == 0){

digitalWrite(r1, HIGH);

}else{

digitalWrite(r1, LOW);

}

if(b > 1000 ) {

b=0;

}

}

void right()

{

digitalWrite(l1, HIGH);

digitalWrite(r1, LOW);

digitalWrite(l2, LOW);

analogWrite(r2, 100);

}

void left()

{

analogWrite(l1, 100);

digitalWrite(r1, LOW);

digitalWrite(l2, LOW);

digitalWrite(r2, HIGH);

}

void stopCar() {

digitalWrite(l1, LOW);

digitalWrite(r1, LOW);

digitalWrite(l2, LOW);

digitalWrite(r2, LOW);

}

void rotr() {

digitalWrite(l1, HIGH);

digitalWrite(r1, LOW);

digitalWrite(l2, HIGH);

digitalWrite(r2, LOW);

}

void rotl(){

digitalWrite(l1, LOW);

digitalWrite(r1, HIGH);

digitalWrite(l2, LOW);

digitalWrite(r2, HIGH);

} #include <Wire.h>

#include <SoftwareSerial.h>

SoftwareSerial BTSerial(10, 11); // CONNECT BT RX PIN TO ARDUINO 11 PIN | CONNECT BT TX PIN TO ARDUINO 10 PIN

const int MPU_ADDRESS = 0x68; // MPU6050 I2C address

float AccX, AccY, AccZ;

float GyroX, GyroY, GyroZ;

float accAngleX, accAngleY, gyroAngleX, gyroAngleY, gyroAngleZ;

float roll, pitch, yaw;

float AccErrorX, AccErrorY, GyroErrorX, GyroErrorY, GyroErrorZ;

float elapsedTime, currentTime, previousTime;

int c = 0;

void setup()

{

Serial.begin(9600);

BTSerial.begin(9600); // HC-05 default speed in AT command more

Wire.begin(); // Initialize comunication

Wire.beginTransmission(MPU_ADDRESS); // Start communication with MPU6050 // MPU=0x68

Wire.write(0x6B); // Talk to the register 6B

Wire.write(0x00); // Make reset - place a 0 into the 6B register

Wire.endTransmission(true); //end the transmission

// Configure Accelerometer Sensitivity - Full Scale Range (default +/- 2g)

/* Wire.beginTransmission(MPU);

Wire.write(0x1C); //Talk to the ACCEL_CONFIG register (1C hex)

Wire.write(0x10); //Set the register bits as 00010000 (+/- 8g full scale range)

Wire.endTransmission(true);

// Configure Gyro Sensitivity - Full Scale Range (default +/- 250deg/s)

Wire.beginTransmission(MPU);

Wire.write(0x1B); // Talk to the GYRO_CONFIG register (1B hex)

Wire.write(0x10); // Set the register bits as 00010000 (1000deg/s full scale)

Wire.endTransmission(true);

delay(20);

//Call this function if you need to get the IMU error values for your module*/

//while(true) calculate_IMU_error();

// delay(20);

}

void loop()

{

MPU_read_accel_data();

MPU_read_gyro_data();

// calculate time elapsed since last time we were here

previousTime = currentTime; // Previous time is stored before the actual time read

currentTime = millis(); // Current time actual time read

elapsedTime = (currentTime - previousTime) / 1000; // Divide by 1000 to get seconds

// Complementary filter - combine acceleromter and gyro angle values

roll = 0.92 * (roll + (GyroX * elapsedTime)) + 0.08 * accAngleX;

pitch = 0.92 * (pitch + (GyroY * elapsedTime)) + 0.08 * accAngleY;

//yaw = gyroAngleZ;

// Currently the raw values are in degrees per seconds, deg/s, so we need to multiply by sendonds (s) to get the angle in degrees

gyroAngleX += GyroX * elapsedTime; // deg/s * s = deg

gyroAngleY += GyroY * elapsedTime;

gyroAngleZ += GyroZ * elapsedTime;

/*by me */

// Print the values on the serial monitor

Serial.print("roll:");

Serial.print(roll);

Serial.print(" ");

Serial.print("pitch:");

Serial.println(pitch);

/* Serial.print(" ");

Serial.print("yaw:");

Serial.println(yaw);*/

/*Serial.print(" ");

/* made by me

// Print the values on the serial monitor

Serial.print(pitch);

Serial.print(" ");

Serial.print(accAngleY);

Serial.print(" ");

Serial.println(gyroAngleY);

*/

if(pitch<-17){

BTSerial.write('F');

}else if(pitch>20){

BTSerial.write('B');

}else if(roll>30){

BTSerial.write('R');

}else if(roll<-30){

BTSerial.write('L');

}else if(yaw>30){

BTSerial.write('r');

}else if(yaw<-30){

BTSerial.write('l');

}else

BTSerial.write('S');

}

void MPU_read_accel_data()

{

// === Read acceleromter data === //

Wire.beginTransmission(MPU_ADDRESS);

Wire.write(0x3B); // Start with register 0x3B (ACCEL_XOUT_H)

Wire.endTransmission(false);

Wire.requestFrom(MPU_ADDRESS, 6, true); // Read 6 registers total, each axis value is stored in 2 registers

//For a range of +-2g, we need to divide the raw values by 16384, according to the datasheet

AccX = (Wire.read() << 8 | Wire.read()) / 16384.0; // X-axis value

AccY = (Wire.read() << 8 | Wire.read()) / 16384.0; // Y-axis value

AccZ = (Wire.read() << 8 | Wire.read()) / 16384.0; // Z-axis value

// Calculating Roll and Pitch from the accelerometer data

accAngleX = (atan(AccY / sqrt(pow(AccX, 2) + pow(AccZ, 2))) * 180 / PI) - (-0.40); // AccErrorX ~(0.58) See the calculate_IMU_error()custom function for more details

accAngleY = (atan(-1 * AccX / sqrt(pow(AccY, 2) + pow(AccZ, 2))) * 180 / PI) - (-3.75); // AccErrorY ~(-1.58)

}

void MPU_read_gyro_data()

{

// === Read gyroscope data === //

Wire.beginTransmission(MPU_ADDRESS);

Wire.write(0x43); // Gyro data first register address 0x43

Wire.endTransmission(false);

Wire.requestFrom(MPU_ADDRESS, 6, true); // Read 4 registers total, each axis value is stored in 2 registers

// For a 250deg/s range we have to divide first the raw value by 131.0, according to the datasheet

GyroX = (Wire.read() << 8 | Wire.read()) / 131.0;

GyroY = (Wire.read() << 8 | Wire.read()) / 131.0;

GyroZ = (Wire.read() << 8 | Wire.read()) / 131.0;

// Correct the outputs with the calculated error values

GyroX = GyroX - (-0.68); // GyroErrorX = ~ (-2.12)

GyroY = GyroY - (-2.48); // GyroErrorY = ~ (4.12)

GyroZ = GyroZ - (-0.12); // GyroErrorZ = ~ (1.20)

}

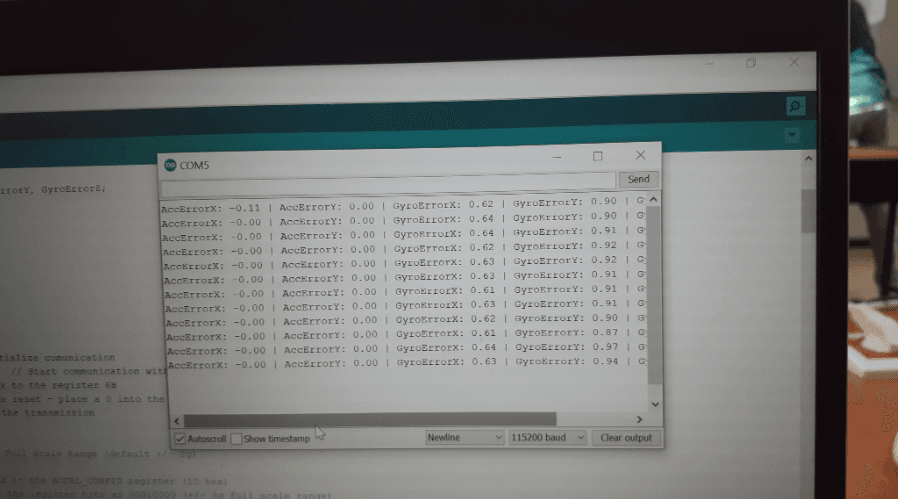

void calculate_IMU_error()

{

// We can call this funtion in the setup section to calculate the accelerometer and gyro data error. From here we will get the error values used in the above equations printed on the Serial Monitor.

// Note that we should place the IMU flat in order to get the proper values, so that we then can the correct values

// Read accelerometer values 200 times

while (c < 200)

{

Wire.beginTransmission(MPU_ADDRESS);

Wire.write(0x3B);

Wire.endTransmission(false);

Wire.requestFrom(MPU_ADDRESS, 6, true);

AccX = (Wire.read() << 8 | Wire.read()) / 16384.0 ;

AccY = (Wire.read() << 8 | Wire.read()) / 16384.0 ;

AccZ = (Wire.read() << 8 | Wire.read()) / 16384.0 ;

// Sum all readings

AccErrorX = AccErrorX + ((atan((AccY) / sqrt(pow((AccX), 2) + pow((AccZ), 2))) * 180 / PI));

AccErrorY = AccErrorY + ((atan(-1 * (AccX) / sqrt(pow((AccY), 2) + pow((AccZ), 2))) * 180 / PI));

c++;

}

//Divide the sum by 200 to get the error value

AccErrorX = AccErrorX / 200;

AccErrorY = AccErrorY / 200;

c = 0;

// Read gyro values 200 times

while (c < 200)

{

Wire.beginTransmission(MPU_ADDRESS);

Wire.write(0x43);

Wire.endTransmission(false);

Wire.requestFrom(MPU_ADDRESS, 6, true);

GyroX = Wire.read() << 8 | Wire.read();

GyroY = Wire.read() << 8 | Wire.read();

GyroZ = Wire.read() << 8 | Wire.read();

// Sum all readings

GyroErrorX = GyroErrorX + (GyroX / 131.0);

GyroErrorY = GyroErrorY + (GyroY / 131.0);

GyroErrorZ = GyroErrorZ + (GyroZ / 131.0);

c++;

}

//Divide the sum by 200 to get the error value

GyroErrorX = GyroErrorX / 200;

GyroErrorY = GyroErrorY / 200;

GyroErrorZ = GyroErrorZ / 200;

// Print the error values on the Serial Monitor

Serial.print("AccErrorX: ");

Serial.print(AccErrorX);

Serial.print(" | AccErrorY: ");

Serial.print(AccErrorY);

Serial.print(" | GyroErrorX: ");

Serial.print(GyroErrorX);

Serial.print(" | GyroErrorY: ");

Serial.print(GyroErrorY);

Serial.print(" | GyroErrorZ: ");

Serial.println(GyroErrorZ);

delay(1000); }

I’ve been browsing online greater than 3 hours lately, but I never found any interesting article like yours. It is pretty value sufficient for me. In my opinion, if all webmasters and bloggers made just right content as you probably did, the web might be a lot more helpful than ever before.